Gas cylinder sizes supplier, mainly located in Asia. The largest suppliers are China (Mainland), Iran (Islamic Republic of) and Hong Kong, which provide 99%, 1% and 1% of the cooking cylinder sizes, respectively. We also offer 10L-50L products.

Cooking cylinder size products are most popular in South America, the Middle East and Oceania.airgas, dimension

What is Gas cylinder?

A cylinder or tank is a pressure vessel used to store and contain gases above atmospheric pressure. High pressure cylinders gas airgas are also called bottles. Inside the cylinder, according to the physical characteristics of the contents, the contents can be stored in compressed gases, vapors in liquids, supercritical fluids or dissolved in matrix materials. Typical cylinder designs are slender, upright at flat bottom, with valves and accessories at the top for connecting to receiving devices.

Cylinder type

- Type 1 = Metal only. Mainly seamless forging metal. But for lower working pressure, such as liquefied butane, there are also welded steel containers.

- Type 2 = Metal containers, rings wrapped in fibrous composites only around the cylindrical part of the “cylinder”. (Geometrically, compared with a cylindrical spherical cap, it is necessary to have twice the tensile strength in the cylindrical area.)

- Type 3 = Thin metal lining (which keeps the container tight but does not affect the working pressure) is completely wrapped with fibers in the matrix material.

- Type 4 = non-metallic lining made of plastic, completely wrapped in fibre material. The center of the cylinder head is still metal and includes the threads of the valve.

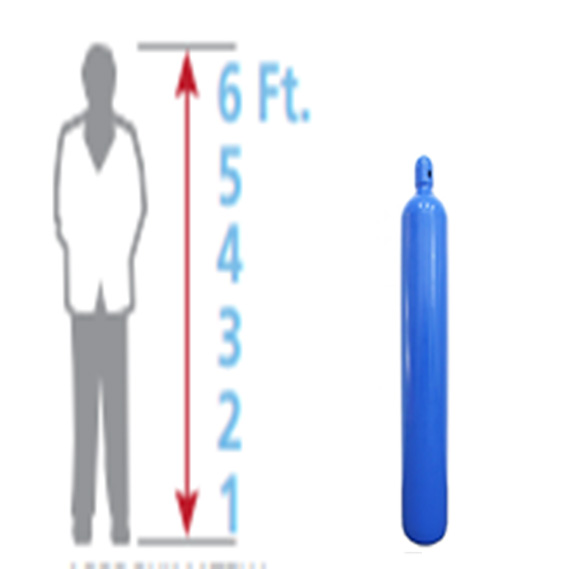

cylinder sizes

Liquefied air provides a variety of packaging options for special gases and industrial gases. We provide high-pressure compressed cylinders of various sizes, with various capacities, suitable for any application. Cylinder assemblies can also be used in applications requiring multiple compressed gas cylinders. In addition, LPG also provides liquid gas mixtures in high-pressure piston cylinders.

For large amounts of hydrogen and helium, high-pressure tube trailers are available. Although most of our cylinders are still the property of Air Liquide Group, we will also fill our customers’own cylinders to meet all appropriate safety requirements.

What are the sizes of oxygen cylinders?

The M2 oxygen cylinder is 5.3 inches high and 2.5 inches in diameter.

The M4 aluminium cylinder is 3.21 inches in diameter and 9 inches in height.

Aluminum ML6 is 4.3 inches in diameter and 7.5 inches in height.

D cylinder is 4.3 inches in diameter and 16.5 inches in height.

How much gas is in a oxygen cylinder?

The full cylinder pressure is about 2500 psi. Or about 180 bars. So. 047 x 180 = about 9 cubic meters. How many liters of oxygen are there in a 7-cubic-meter cylinder? No oxygen cylinder only oxygen?

Gas cylinder sizes and prices specifications

| Water Capacity | Weight(lbs)* | Price | Valve |

| 49-50 | 150 | $500 | 60 |

| 43-44 | 125 | $400 | 56 |

| 27-28 | 70 | $300 | 47 |

| 16-17 | 53 | $200 | 36 |

| 16-17 | 38 | $100 | 28 |

| 10-11 | 31 | $50 | 23 |

Acetylene Cylinders

| Size/Name | Width | Weight | Height |

| ESC | 4” | 8 lbs | 15” |

| ESB | 6” | 25 lbs | 23” |

| ES75 | 7” | 43 lbs | 31” |

| ES#4 | 8” | 70 lbs | 40” |

| ES#5 | 12” | 145 lbs | 40” |

How much gas is in a oxygen cylinder?

The full cylinder pressure is about 2500 psi. Or about 180 bars. So. 047 x 180 = about 9 cubic meters. How many liters of oxygen are there in a 7-cubic-meter cylinder? No oxygen cylinder only oxygen?

What is the dimension of a 14.2 kg LPG cylinder?

The manufacturer must prepare detailed drawings for the cylinders filled with liquefied petroleum gas (LPG) according to the above-mentioned cylinder diagrams and all other requirements of HP C. The greatest working pressure airgas of the LPG at 65 degrees C is 1.66 Mpa.The wall thickness of finished cylinder should be calculated by including extra thickness to cover. the corrosion margin and stress during transportation.

The approval of more thickness and final wall thickness obtained should also be calculated by design. More thickness of corrosion margin/stress due to transportation must be approved by CCOE, but not less than 0.1mm. The wall thickness of the finished cylinder should not be less than 2.53 mm. Only after these approvals can the manufacture of cylinders begin.

Confirm that the self-closing valves conforming to IS:8737 (latest) specifications and with BIS test certificate must be purchased by the cylinder manufacturer from the HPC-approved SC valve manufacturer. A list of SC dimension valve manufacturers approved by HPC is attached. When purchasing valves, the BIS test certificate of valves and copies of the valves produced in the factory and other documents submitted to the factory when supplying cylinders should be arranged.

For all necessary materials, testing must be performed only in NABL accredited laboratories. If the supplier is the manufacturer of the product and has obtained BIS approval of the product, the supplier’s test certificate is acceptable. HPCL reserves the right to test materials at supplier’s cost.From time to time, the company may recommend changes in any size the manufacturer must follow,gas cylinder sizes airgas applicable tolerances, and preparation methods of welded joints, etc.

successful bidders must follow any changes in safety slogans or other details of screen printing on cylinders.All materials, such as SC valves, safety hats, including designed hats, should be purchased only from parties approved by HPC. Records of all received materials, batch numbers, test certificates, BIS certificates of SC valves, etc. must be kept by the supplier for future HPCL inspection.

Besides, it is important to ensure that suppliers buy valves with the same distribution of cylinder supply. But, if the dimension of supply cylinders is given in the first month of this quarter, the manufacturing date of the valve may be the previous quarter.