GGD type AC low-voltage distribution cabinet is the former Ministry of Energy to promote the technical progress of China’s low-voltage distribution industry, accelerate the renewal of low-voltage distribution switchgear for the purpose. In 1991, it was issued as a development project for technological progress. The design and development was completed by the Joint Design and Development Group of Low-voltage Switchgear of the Ministry of Energy (NL S for short). In October 1992, it passed the ministerial appraisal hosted by the Ministry of Energy. At present, it is widely used throughout the country.

GGD type AC low-voltage distribution cabinet is suitable for power plants, power stations, factories, mines and other power users of AC 50Hz, rated working voltage 380V, rated working current up to 3200A power distribution system, as power, lighting and distribution equipment for power conversion, distribution and control. GGD type AC low-voltage distribution cabinet is a new type of low-voltage distribution cabinet designed according to the requirements of the majority of electric power users and the design department, and based on the principles of safety, economy, reasonableness and reliability.

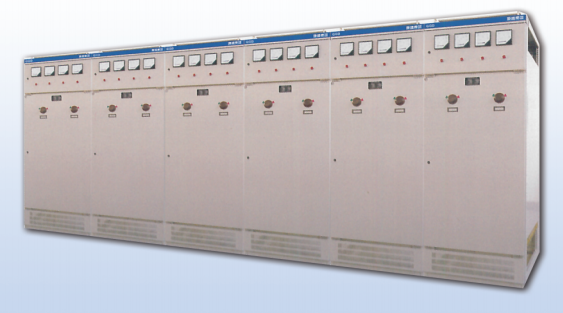

The product has the features of high breaking capacity, good dynamic and thermal stability, flexible electrical scheme, convenient combination, series, strong practicality, novel structure and high protection level. GGD type AC low-voltage distribution cabinet complies with IEC60439 “Low-voltage complete sets of switchgear and control equipment”, GB7251 “Low-voltage complete sets of switchgear and control equipment” and other standards.

G AC Low Voltage Distribution Cabinet

G Fixed installation of electrical components, fixed wiring

D motive power

1- Breaking capacity 15kA

2- Breaking capacity 30kA

3- Breaking capacity 50kA

Conditions of use

★ The surrounding air temperature is not higher than +40℃, not lower than -5℃, and the average temperature in 24h is not higher than +35C.

★ Indoor installation and use, the altitude of the use of the location does not exceed 2000m.

★ The relative humidity of the surrounding air does not exceed 50% at a maximum of +40C, and a larger relative humidity is allowed at lower temperatures. (e.g. 90% at +20C) The effect of condensation due to temperature changes may occur occasionally should be taken into account.

★ The equipment should be installed with an inclination of no more than 5% from the vertical.

★ The equipment should be installed in a place where there is no severe vibration or shock, and where there is insufficient corrosion of the electrical components.

★ Users with special requirements can be negotiated with the manufacturer.

| Model No. | Rated voltage (V) | Rated current (A) | Rated short-circuit breaking current(kA) | Rated short-time withstand current (1s)(kA) | Rated peak withstand current(kA) |

| GGD1 | 380 | 1000/630/400 | 15 | 15 | 30 |

| GGD2 | 380 | 1613/1000 | 30 | 30 | 63 |

| GGD3 | 380 | 3200/2500/200 | 50 | 50 | 105 |

Main circuit scheme

The main circuits of GGD cabinets are designed with 129 schemes and a total of 298 specifications (excluding schemes and specifications derived from functional changes in auxiliary circuits and changes in control voltage).

Among them, GGD1 type 49 programmes 123 specifications

GGD2 type 53 programmes 107 specifications

GGD3 type 27 programmes 68 specifications

The main circuit schemes have been selected in consultation with a wide range of design and user departments. The programme for power plants has been added. The rated current is increased to 3200A, which is suitable for 2000KVA and below distribution transformers.

In addition, in order to adapt to the needs of reactive power compensation designed GGJ1, GGJ2 capacitor compensation cabinet, its main circuit scheme 4, a total of 12 specifications.

Structural characteristics

★ GGD-type AC low-voltage distribution cabinet cabinet adopts the form of universal cabinet, the frame is assembled by 8MF pulling and refrigeration bending steel assembly and local welding, and the frame parts are exclusively used for supporting parts supplied by the designated steel production plant to ensure the accuracy and quality of the cabinet. The parts of the universal cabinet are designed according to the modular principle, and there are mounting holes of 20 moulds, with a high coefficient of universality. It can make the factory realise pre-production, which not only shortens the manufacturing cycle of the products, but also improves the working efficiency.

★ GGD cabinet design fully considered the operation of the cabinet heat dissipation problems, in the cabinet at the upper and lower ends are not a different number of cooling slots, when the cabinet electrical components heat up, the heat rises, through the upper end of the slots discharged, and the cold air constantly from the lower end of the slots supplemented by the cabinet, so that sealed cabinets from the bottom up to form a natural air duct, to achieve heat dissipation purposes.

★ GGD cabinet is designed according to the modern industrial product modelling design requirements, and the method of golden section ratio is used to design the cabinet exterior and the section size of each part, which makes the whole cabinet beautiful and generous, with a new look. ★ The cabinet door is connected with the frame by pivot-type movable hinge, which is convenient for installation and disassembly. The folded edge of the door is embedded with a mountain-type rubber moulding strip, and the embedded strip between the door and the frame has a certain compression stroke when the door is closed, which can prevent the door and the cabinet from direct collision, thus improving the protection level of the cabinet. The instrument door with electrical components is connected to the frame with a multi-strand soft copper wire. The mounting parts inside the cabinet are connected to the frame with knurled screws, and the whole cabinet constitutes a complete grounding protection circuit. The decent paint of the cabinet is polyester orange baking paint with strong adhesion and good texture. The whole cabinet is in matte colour, avoiding the glare effect, creating a comfortable visual environment for the personnel on duty.

The top cover of the cabinet can be dismantled when needed, which is convenient for the assembly and adjustment of the main busbar on site, and the four corners of the cabinet top are equipped with lifting rings for lifting and loading.

★ The protection grade of the cabinet is IP30, and users can choose between IP20~IP40 according to the requirements of the use environment.

Ordering instructions

★ When ordering, the user should provide the following information.

★ Main circuit scheme and combination arrangement

★ Auxiliary circuit control and wiring principle

★ Layout of the switchgear in the distribution room.

★ Incoming and outgoing wires and interface requirements

★ Detailed models and specifications of the components installed in the cabinet.

★ Switchgear surface treatment and colour

★ Other special requirements (if any)